Our history

From Industrial Projects to a Harvester Head Manufacturer

Outokummun Metalli Oy was founded in 1980 by engineer Pekka Nevalainen together with three partners. Until the early 2000s, the company’s core business consisted of industrial projects, specializing in material handling equipment for the mining and process industries, such as belt conveyors and storage silos. Over the years, production also included LPG cylinders, piece positioner equipment, and a wide range of subcontracted mechanical engineering work.

Development of forestry harvester heads began as an in-house product in 1984. Over time, this evolved into the company’s primary business and long-term growth driver.

In 2003, Outokummun Metalli established a joint venture Waratah OM Oy with Timberjack (a John Deere Company). Product development, product support, and final assembly of harvester heads were transferred to Waratah OM, while Outokummun Metalli focused on manufacturing frames and welded main components. Gradually, the company exited industrial projects and other product lines to concentrate fully on harvester head manufacturing.

Through systematic development and major investments, Outokummun Metalli has grown into a modern contract manufacturing facility specializing in heavy steel structures. Today, its core business is the frame production of John Deere and Waratah harvester heads. Since 2011, the company has also manufactured VAHVA grapples.

Company Founding

After ten years as a mechanical engineering professional at Outokummun Konepaja Oy, Pekka Nevalainen decided to establish his own company. Together with Paavo Pietarinen, Auvo Ratilainen, and Tarmo Tahvanainen, Outokummun Metalli Oy was officially founded on May 9, 1980.

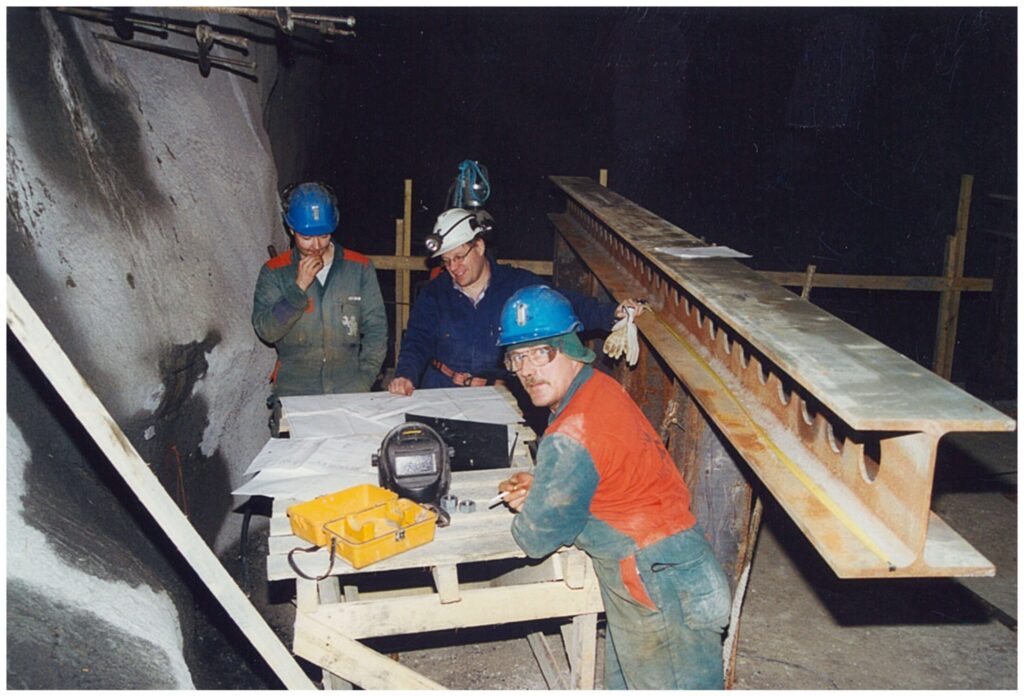

The company’s founding principle was clear: to provide mechanical workshop and installation services distinguished by quality and delivery reliability. Early operations began in rented facilities in Outokumpu, with the first project launched in June 1980 at the Vuonos mine. As the business grew, the company moved into larger, purpose-built facilities in the Sysmäjärvi industrial area in 1983.

Industrial Maintenance and Projects in the 1980s

During its early years, Outokummun Metalli established itself as a trusted partner in industrial maintenance. Key customers included e.g. Outokumpu Oy, Myllykoski Oy, Enso-Gutzeit Oy, and Oy Wilh. Schauman Ab. Core expertise covered conveyor maintenance, piping modifications, and machinery relocation.

Alongside maintenance services, the company expanded into bid-based workshop manufacturing and large-scale project deliveries. Major projects included machinery and equipment installations for Outokumpu’s Keretti mine pilot plant, Myllykoski’s Luikonlahti plant, and Outokumpu’s Enonkoski mine. During this period, a long-term customer relationship was established also with Finnminerals, for which Outokummun Metalli supplied equipment to the Vuonos talc slurry plant. By the end of the decade, the company was well recognized as a supplier of custom-designed bulk material handling equipment.

Project Business in the 1990s and Early 2000s

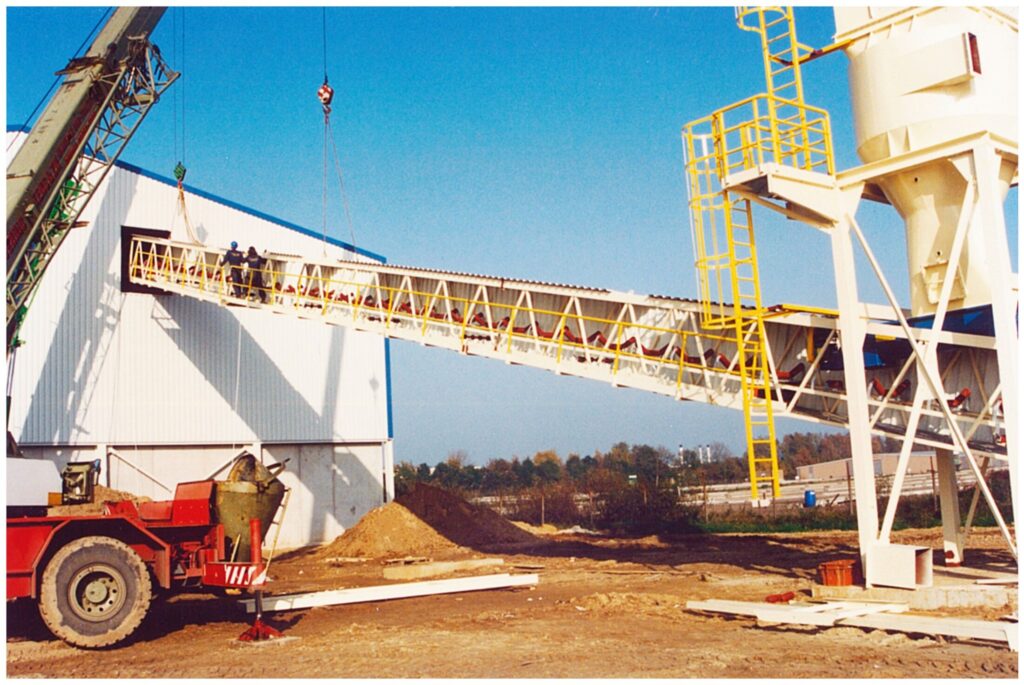

During the 1990s, Outokummun Metalli became a key equipment supplier to Finnminerals (later Mondo Minerals) as the company expanded its talc operations into Central Europe. In 1993, Finnminerals built a new talc processing plant in Cuijk, the Netherlands, for which Outokummun Metalli delivered the complete mechanical scope. The delivery included process machinery, equipment, tanks, piping systems, and on-site installation. Outokummun Metalli also supplied equipment to the Joensuu harbour, built for bulk talc logistics.

In Finland, the company executed several significant industrial projects. These included steel structures and service platforms for Enocell’s pulp mill, chemical station equipment and crusher conveyors for Mondo Minerals’ plant, as well as sulfur concentrate unloading stations and conveyor systems for Kemira Chemicals.

In the early 2000s, the largest single industrial project in the company’s history was launched at the Pyhäsalmi mine. Outokummun Metalli supplied and installed the mine’s ore handling systems, including more than 400 meters of conveyors and heavy-duty steel support structures. Several other large-scale projects followed, such as the ore handling conveyor system for AvestaPolarit Chrome’s Kemi mine in 2002–2003.

In 2008, Outokummun Metalli delivered conveyor systems to Talvivaara Mining Company. This marked the company’s final industrial project, after which all resources were redirected toward the rapidly growing harvester head business.

Product Development Alongside Industrial Projects

Alongside project business, Outokummun Metalli actively sought proprietary products to balance the cyclical nature of industrial projects. From the early years onward, various product concepts were explored through both international trade fairs and domestic channels.

Several product lines were introduced over time. Harvester head product rights were acquired in 1984, forming the foundation of the company’s future core business. Steel LPG cylinders were manufactured from 1986 to 1997. New Firo piece positioners were produced between 1991 and 2008, and Neka-System sludge handling equipment for wastewater treatment plants was manufactured from 1994 to 1997.

Harvester Head Product Development

In 1984, Outokummun Metalli acquired the product rights to a harvester head originally developed by the company Finncombi. Design engineers Veikko Kettunen and Jussi Makkonen subsequently joined Outokummun Metalli, enabling further product development and the start of serial production.

Outokummun Metalli’s first in-house harvester head model was the 750H. Developed in close cooperation with customers, it formed the foundation of the company’s long-term product development capabilities. The 750H was followed by the 756 and its improved version, the 756B, which introduced a key technical change by relocating the hydraulic valve from the base machine to the harvester head.

The next models were the 755 and later the 755B. A major breakthrough was achieved with the launch of the 745 model in 1995. This model featured four feed rollers (4WD), a lighter structure, a new sawing unit, and a multi-tree handling function. It gained wide acceptance in the market and effectively established the well-known term “the Outokummun head” among forestry contractors, even though the products were not marketed under the Outokummun Metalli name.

Alongside the 745, heavier-duty models 758 and 758HD were developed, with the 758HD becoming the main product for particularly demanding operating conditions. The 745 platform was further developed into the H754 model, which remained in production until 2017. The final harvester head model designed at Outokummun Metalli was the highly regarded H480.

Outokummun Metalli carried out pioneering work in the development of forest harvesting equipment and introduced numerous technical solutions that are still in use in modern harvester heads today. Sales of the harvester heads manufactured by Outokummun Metalli were initially handled by Lokomo Forest Oy, part of the Finnish Rauma-Repola Group. Following subsequent acquisitions, sales responsibility transferred to Timberjack and later to John Deere Forestry.

Joint Venture and Investment in Production

In 2000, the company’s sales partner changed to the American Deere & Company, which acquired Timberjack. Following a restructuring of Deere’s forestry equipment operations, Outokummun Metalli and Timberjack established a new joint venture in 2003, named Waratah OM Oy.

Waratah OM assumed responsibility for harvester head design, product support, and final assembly, including hydraulic and electrical installations. Sales and marketing remained with Timberjack. Outokummun Metalli’s role focused on manufacturing all harvester head frames and welded main components, performing mechanical assembly, and supplying the spare parts included in the frame deliveries.

To support this shift and specialization in harvester head production, Outokummun Metalli launched its first major investment program at the Sysmäjärvi plant in 2003–2004. In addition to new machinery, the facility was expanded by nearly 3,000 square meters, including a dedicated machining hall, a new welding hall, and modern office spaces. These investments elevated the company’s manufacturing capabilities to a completely new level and enabled a strong focus on efficient steel structure production.

Building the Group Structure

Outokummun Metalli became a family-owned company in 2002, when three of the founding shareholders retired and the Nevalainen family continued operations. At the same time, the company established a new strategic foundation, supported by active board-level governance.

The renewed strategy defined a clear focus on forestry-related business and set the objective of growing the company through both proprietary products and contract manufacturing.

Strategy execution was accelerated through two acquisitions. In 2009, the company acquired a stake in Pentin Paja Oy to participate in the development of energy wood harvesting products. In 2011, the acquisition of Koneosapalvelu Oy Aliranta expanded the company’s operations to include own brands as well as spare parts, components, and maintenance services.

Koneosapalvelu became a subsidiary, and a group structure with shared finance, HR, and ICT functions was developed. Production of the VAHVA grapple product range was gradually transferred to Outokummun Metalli starting in 2011.

A second major production investment program was carried out in 2007–2008 as harvester head markets continued to grow. Investments included a new paint shop, a new assembly hall, expanded employee facilities, a machining center, and a welding robot.

Continuous Development of Manufacturing Operations

From the early 2010s onward, operations at the Sysmäjärvi plant increasingly focused on contract manufacturing and the systematic development of production processes and technologies. Objectives included increased automation, higher production capacity, improved product quality, and enhanced occupational safety and employee well-being.

ISO 9001 quality management and ISO 3834-2 welding certifications were implemented in 2010. Subsequent development initiatives included robotic welding cells in 2018 and 2022, next-generation machining centers (Okuma in 2019 and DN Solutions in 2023), digital production control systems, and the use of 3D scanning technology.

In 2023, the facilities were expanded with a new assembly hall, accompanied by a complete renewal of the assembly line. The occupational health and safety management system was certified to ISO 45001 in 2025, and the environmental management system to ISO 14001 in the same year.

The story of Outokummun Metalli continues under new leadership: In June 2025, the company experienced only the second CEO transition in its history, when Zoltan Toth was appointed as CEO. He succeeded Jarmo Paakkunainen, who had led the company for 18 years. The company’s founder, Pekka Nevalainen, had served as CEO for 27 years, from the company’s founding until 2007.