Factory and equipment

Welcome to learn more about Outokummun Metalli’s operations

Our facilities are located in Outokumpu, North Karelia, Finland. Our 8,280 m² property includes facilities for material storage, welding, machining, painting, assembly, and spare parts operations, as well as office and staff amenities. We do not stock finished products; instead, we deliver them directly to customers as soon as they are completed. Adjacent to our factory is our own heat plant, where we produce most of our heating energy using low-emission wood chips.

Comprehensive machinery for steel product manufacturing

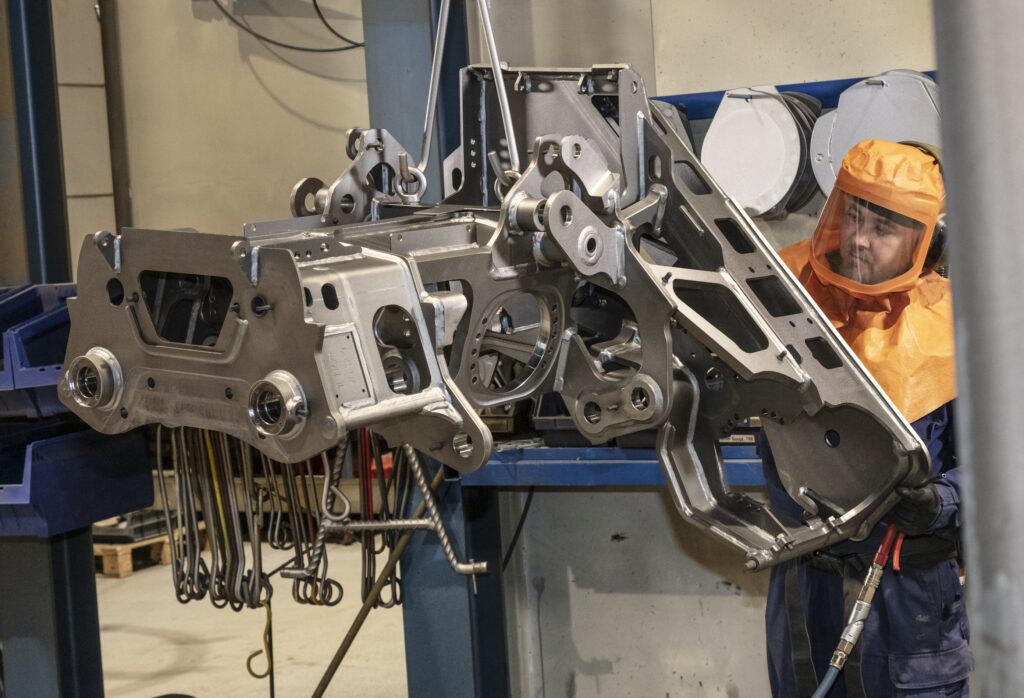

Before production begins, our efficient materials team ensures that the necessary materials and components are available and well-organized. We procure steel in ready-made sheets, but we perform the bending by our own machine. We have placed special emphasis on developing welding methods. Our welding shop includes two automated multi-robot cells and 30 manual welding stations equipped with New Firo workpiece positioner equipment. In quality assurance, we utilize a modern 3D scanner that allows us to quickly compare the measurement results of 3D-scanned surfaces with the dimensions of CAD models, for example, after welding.

Under the guidance of machinists, we operate six vertical machining centers. Additionally, the machining department is equipped with a long milling machine and a lathe. Our newest machining center, the DNS HM 1250, was put into operation in 2023. The painting shop features a shot blasting machine, a powder coating booth, and an oven. A completely renovated assembly line in a new hall was completed in 2023. The line operates with four mobile assembly stations equipped with modern workpiece positioners.

A pioneering approach to method and system development

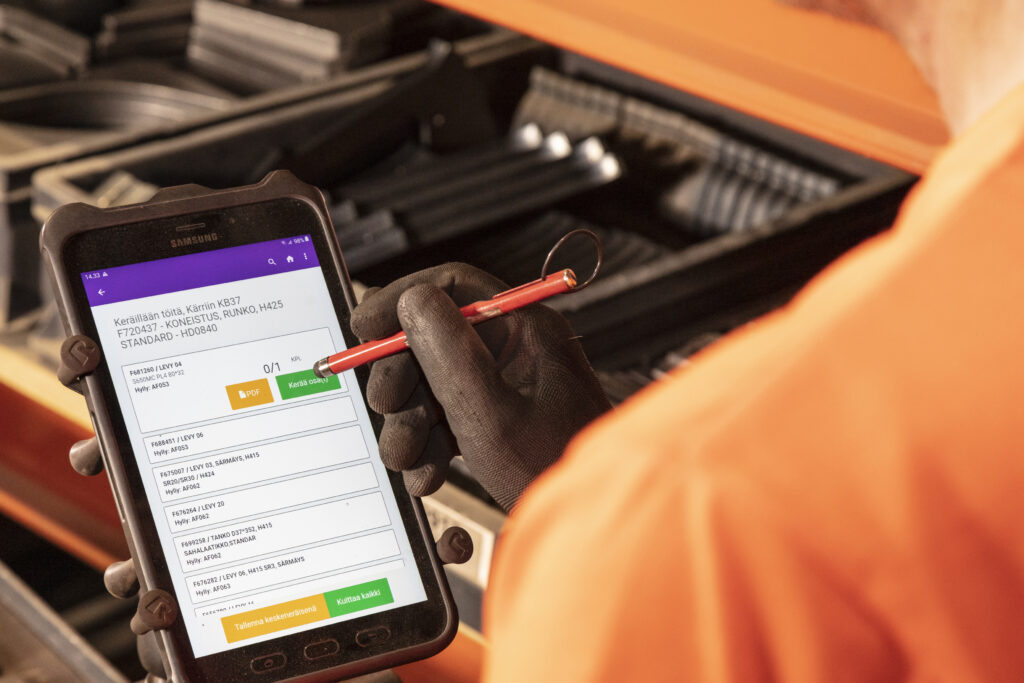

We manage production with a digital system that is clearly visualized within the production facilities, tailored to our needs. We no longer deal with paper; instead, annotations and instructions related to work stages are handled via mobile devices.

We approach the development of new working methods with clear objectives and regularly invest in machinery and systems. These investments allow us to respond to evolving customer needs while improving product quality, operational efficiency, and workplace safety.

People in the spotlight

Even though our facilities are equipped with a wide range of machines and automation has increased dramatically, we would not be able to complete any products without our skilled employees. Our company offers various job roles in both production and administration, including positions such as welder, robot operator, machinist, assembler, welding coordinator/IWS, quality specialist, production engineer, production manager, designer, and purchasing manager. We have a great team, and we place a strong emphasis on their workplace well-being. If you are interested in working in a modern industrial company, please read more on our Careers page!

Watch a video of our factory’s production process

In this time-lapse video, you’ll see a glimpse of our operations from the material warehouse through welding, machining, and painting all the way to assembly.