21.03.2022

Accurate quality control with a 3D scanner

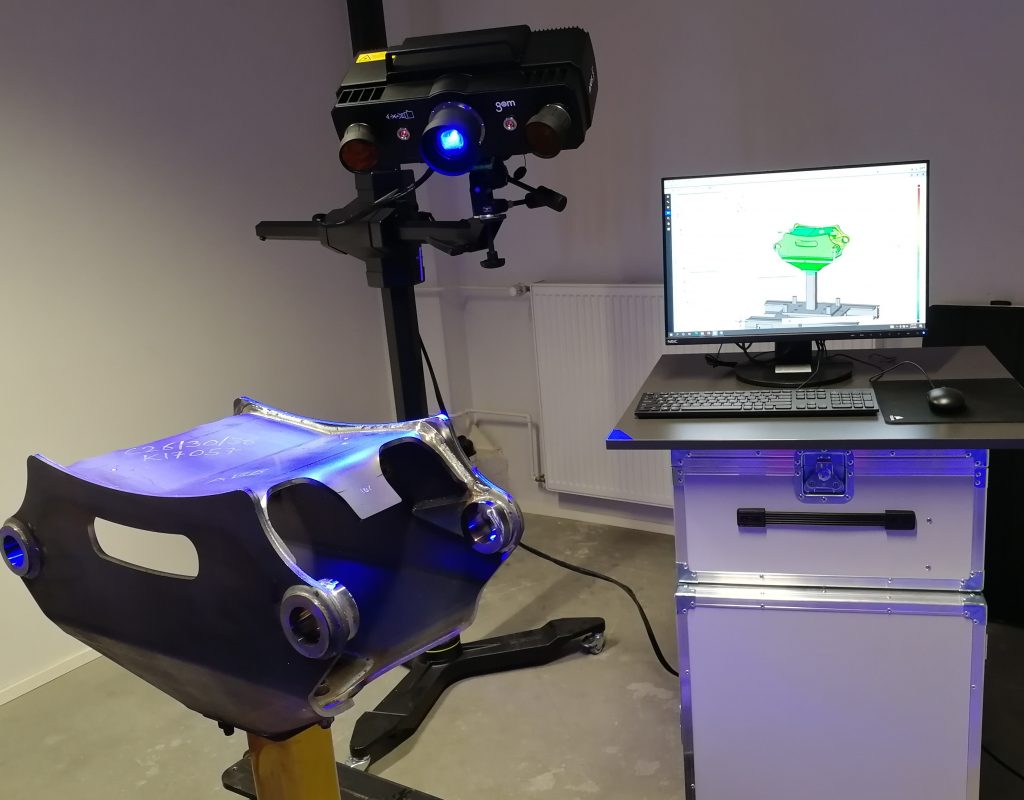

We recently acquired a new 3D measuring device that makes quality assurance in the harvester head manufacturing process even more accurate and faster. The innovative Gom Atos 5 3D scanner combined with GOM inspect pro software produces highly accurate data at high speed.

Quality control in the production process

We are able to quickly compare the measurement results of 3D scanned surfaces with the dimensions of CAD models. Quality assurance is easily achieved at various stages of production, such as welding and machining. With the help of the device, any hidden errors are visualized, and we are able to react quickly to the root causes of the deviations. As a manufacturer of harvester heads, it is important to us that the geometric tolerances of complex parts can be measured reliably. In addition to our own manufacturing, we can also utilize scanning technology to verify the quality of components from suppliers.

The measuring device also helps in the development of production

In addition to the actual manufacturing process, the new 3D measuring device assists in our production development activities, such as the introduction of new manufacturing methods. The measurement can be done live and with a touch probe, which we utilize in the adjustment of jigs and fasteners and in ensuring the positioning of parts. In the future, the device will also enable robotic measurement.

Systematic work for top quality

Continuous development and the use of the latest technology is a natural way for us to work. Our ongoing investment program will bring many innovations to our operating environment in 2022–2023.